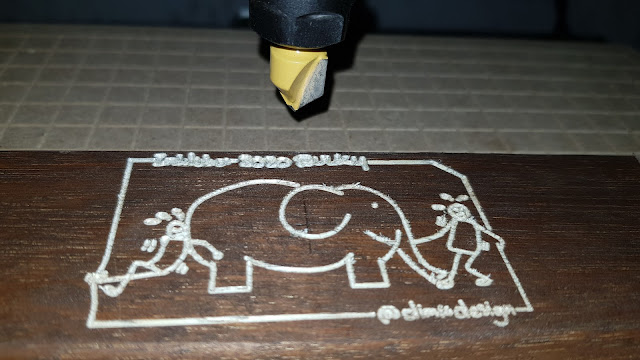

#Inktober 2020 engravings

A friend of mine, Dimitri, set himself a doodling challenge for October 2020: take a single word, and make a little drawing with that word as the topic. And do this every day of the month of October 2020. He called it Inktober 2020. I took two of his drawings, and turned them into engravings on my SainSmart Genmitsu 3018 PROVer. With Vecctric's Aspire (or V-Carve for that matter), it is quite easy to do a vector trace of a black and white picture, so the toolpaths and G-codes were quickly created. I have about 200 of those little 147x45z12mm Laced Acacia wood planks (leftovers from IKEA RUNNEN wood tiles) laying around, so they made excellent test pieces! I used a 60 degree V-bit for this first project. @dimiris_d's Inktober 2020 "Bulky" The V-bit is a little stump for smaller details, so the text gets a little hard to read on this small scale, The second one I decided to try was "Sleep". This time, I wanted to pocket out the area that was going to be engrav